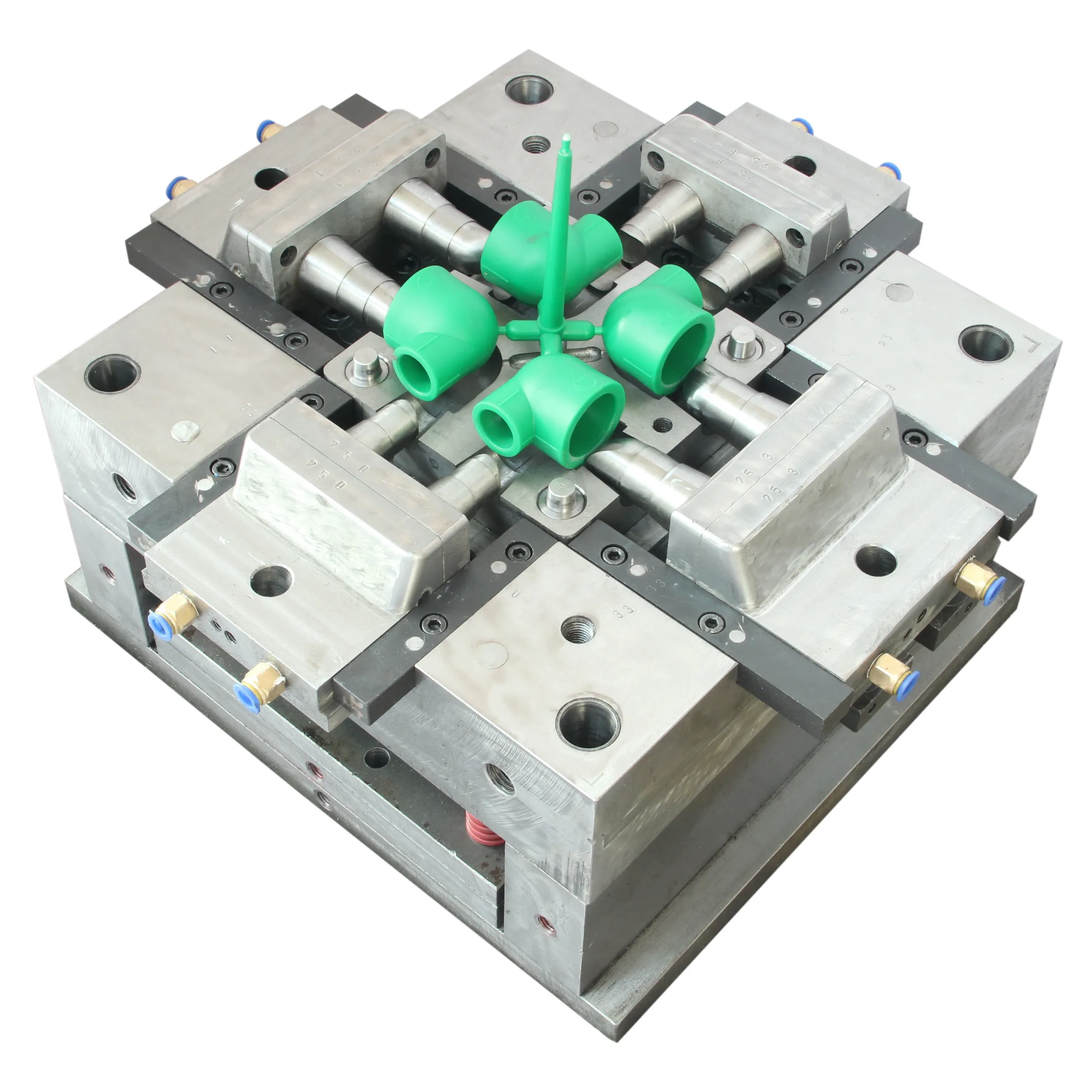

PP-R 이중 시트 사출 금형

PP-R Double Seat Injection Mold: A Comprehensive Overview The PP-R Double Seat Injection Mold is a specialized tool designed for manufacturing high-quality polypropylene random copolymer (PP-R) double-seat fittings, which are widely used in plumbing and piping systems. These molds are engineered to produce components with precise dimensions, excellent surface finish, and superior mechanical properties, ensuring reliable performance in hot and cold water distribution systems. Key Features and Design Considerations 1. Material Compatibility The mold is optimized for PP-R, a thermoplastic material known for its high-temperature resistance, chemical stability, and durability. The design ensures uniform material flow and minimal shrinkage during the injection molding process, resulting in consistent part quality. 2. Double-Seat Configuration The mold is tailored to produce double-seat fittings, which feature two integrated sealing surfaces for secure connections. This design enhances leak-proof performance and simplifies installation in piping networks. 3. High-Precision Cavity and Core The cavity and core are machined with tight tolerances to achieve accurate inner and outer diameters. Advanced CNC machining and EDM (electrical discharge machining) techniques are employed to ensure dimensional stability and longevity. 4. Cooling System Optimization An efficient cooling system is integrated into the mold design to reduce cycle times and prevent warping or deformation. Proper cooling channels enhance productivity while maintaining part consistency. 5. Ejection Mechanism The mold incorporates a reliable ejection system to smoothly release the molded parts without damage. Options include pin ejection, sleeve ejection, or air-assisted ejection, depending on the part geometry. 6. Surface Finishing Critical mold surfaces are polished or textured to achieve the desired finish on the final product. A smooth finish reduces friction during demolding and improves corrosion resistance. Applications PP-R double-seat fittings produced by this mold are essential in residential, commercial, and industrial plumbing systems. They are commonly used in: - Hot and cold water supply lines - Heating systems - Compressed air pipelines - Chemical fluid transport Advantages of Using PP-R Double Seat Injection Molds - High Efficiency: Fast cycle times and automated production capabilities. - Durability: Robust mold construction ensures long service life. - Consistency: Produces uniform parts with minimal defects. - Cost-Effectiveness: Reduces material waste and labor costs. Conclusion The PP-R Double Seat Injection Mold is a critical tool for manufacturing high-performance piping components. Its precision engineering, optimized cooling, and reliable ejection mechanisms make it indispensable for producing leak-proof, durable fittings. By leveraging advanced molding techniques, manufacturers can achieve superior product quality while maintaining cost efficiency. This mold plays a vital role in modern plumbing systems, ensuring safe and efficient fluid transport across various applications.

제품

범주:

-

40mm PPR 팔꿈치 90도 파이프 피팅 금형

분류: PPR 파이프 피팅 금형조회수: 515번호:릴리스 시간: 2025-10-23 18:12:1040mm PPR 팔꿈치 90도 파이프 피팅 금형금형 이름:40mm PPR 팔꿈치 90도 파이프 피팅 금형공동:2개의 공동금형 크기: 20-50mm금형강: 캐비티 및 코어용 2738 또는 718게이트:직통 게이트금형 구조 : 대각선 가이드 컬럼 슬라이더 구조코어/캐비티 경도: 진공 열처리 후 HRC 32-45도사출성형기 : 250TTaizhou Huangyan Hong Jin Mold Co., Ltd는 2002년에 설립되었습니다. 우리는 23년 이상 동안 파이프 피팅 금형을 설계하고 제조하는 전문 기업입니다.우리는 당신과의 오랜 협력을 기대하고 있습니다.다음은 참고하실 수 있는 주요 정보입니다.FAQ:1. 귀하의 MOQ는 무엇입니까?1 세트는 괜찮습니다2. 배송 시간은 어떻게 되나요?배달 시간은 약...

뉴스

범주:

검색 결과가 없습니다!

케이스

범주:

비디오

범주:

검색 결과가 없습니다!

다운로드

범주:

검색 결과가 없습니다!

모집

범주:

검색 결과가 없습니다!

추천 제품

검색 결과가 없습니다!

왓츠앱

왓츠앱 핸드폰

핸드폰