PP-R 브리지 벤드 파이프 몰드

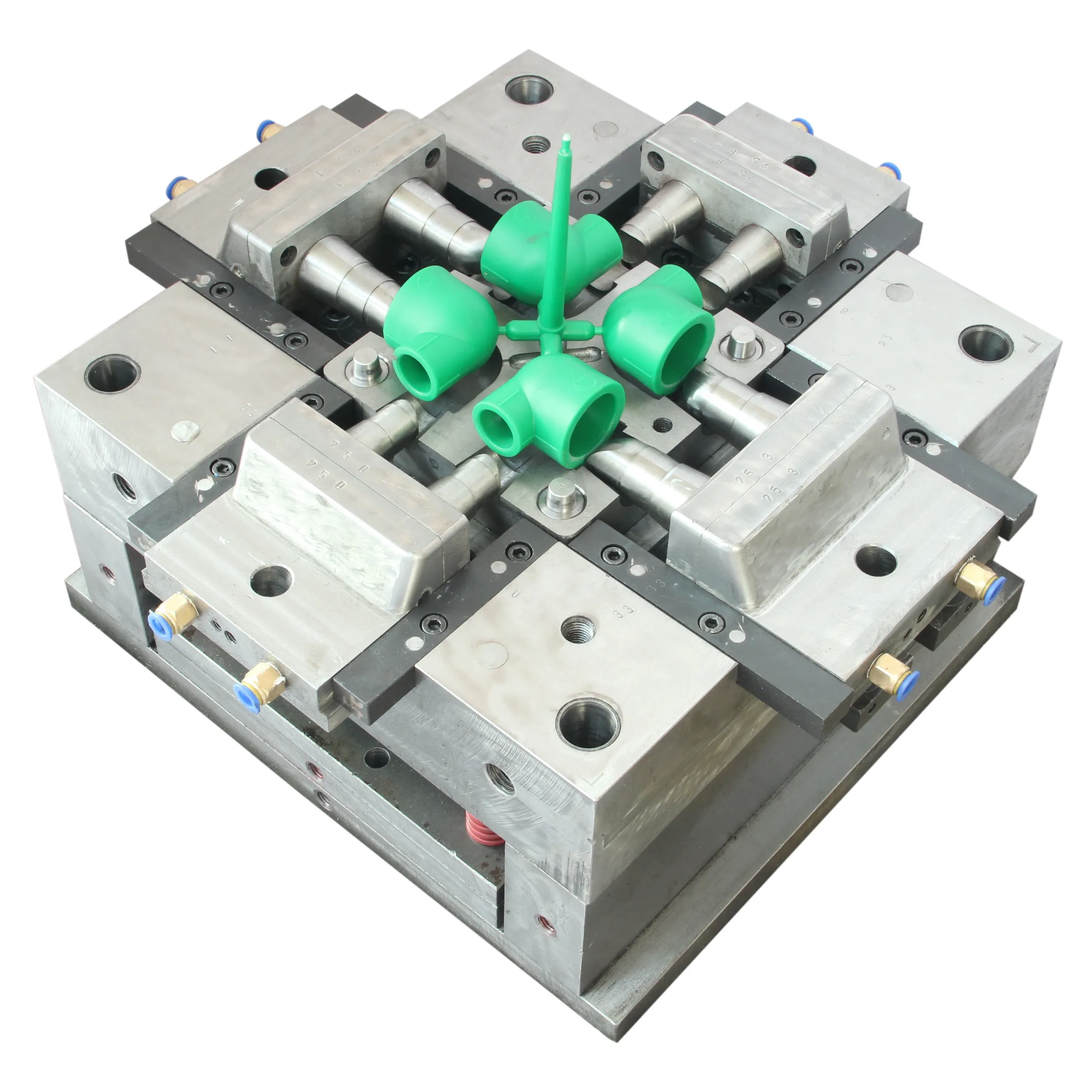

PP-R Bridge Bend Pipe Mold: A Comprehensive Overview The PP-R bridge bend pipe mold is a specialized tool designed for manufacturing polypropylene random copolymer (PP-R) bridge bend pipes, which are widely used in plumbing, heating, and industrial fluid transport systems. These molds are engineered to produce high-quality, durable, and leak-proof pipe fittings that meet stringent industry standards. Below is a detailed description of the PP-R bridge bend pipe mold, covering its design, functionality, material considerations, and advantages. Design and Structure The PP-R bridge bend pipe mold is precision-engineered to create seamless, smooth, and accurately angled pipe bends. The mold typically consists of two main components: the core and the cavity. The core defines the internal diameter and shape of the pipe, while the cavity forms the external surface. The mold is designed to accommodate various bend angles, commonly 45° and 90°, ensuring compatibility with different piping system requirements. Key design features include: - High-Precision Machining: Ensures dimensional accuracy and smooth inner/outer surfaces to minimize friction and pressure loss in fluid flow. - Cooling Channels: Integrated cooling systems facilitate rapid and uniform cooling of the molten PP-R material, reducing cycle times and improving production efficiency. - Interchangeable Inserts: Allows for flexibility in producing different pipe diameters and bend angles without requiring a complete mold replacement. Material and Durability PP-R bridge bend pipe molds are typically made from high-grade tool steel or hardened stainless steel to withstand high temperatures and pressures during injection molding. The mold surfaces are often treated with advanced coatings (e.g., chromium or nickel plating) to enhance wear resistance, reduce friction, and prolong service life. Manufacturing Process The production of PP-R bridge bend pipes involves injecting molten PP-R material into the mold under high pressure. The material fills the mold cavity, taking the shape of the bend before cooling and solidifying. The mold’s precision ensures consistent wall thickness, smooth transitions at the bend, and strong molecular bonding for leak-proof joints. Advantages of PP-R Bridge Bend Pipe Molds 1. High Efficiency: Optimized cooling systems and durable materials enable fast production cycles. 2. Consistent Quality: Precision engineering ensures uniformity in pipe dimensions and mechanical properties. 3. Versatility: Compatible with various PP-R formulations and adaptable to different pipe specifications. 4. Longevity: Robust construction and surface treatments minimize wear and maintenance needs. Applications PP-R bridge bend pipes produced using these molds are essential in: - Residential and commercial plumbing systems. - Underfloor heating installations. - Industrial fluid transport for chemicals and compressed air. Conclusion The PP-R bridge bend pipe mold is a critical tool for manufacturing reliable, high-performance pipe fittings. Its advanced design, material durability, and precision engineering contribute to efficient production and superior product quality, making it indispensable in modern piping systems.

제품

범주:

-

40mm PPR 팔꿈치 90도 파이프 피팅 금형

분류: PPR 파이프 피팅 금형조회수: 515번호:릴리스 시간: 2025-10-23 18:12:1040mm PPR 팔꿈치 90도 파이프 피팅 금형금형 이름:40mm PPR 팔꿈치 90도 파이프 피팅 금형공동:2개의 공동금형 크기: 20-50mm금형강: 캐비티 및 코어용 2738 또는 718게이트:직통 게이트금형 구조 : 대각선 가이드 컬럼 슬라이더 구조코어/캐비티 경도: 진공 열처리 후 HRC 32-45도사출성형기 : 250TTaizhou Huangyan Hong Jin Mold Co., Ltd는 2002년에 설립되었습니다. 우리는 23년 이상 동안 파이프 피팅 금형을 설계하고 제조하는 전문 기업입니다.우리는 당신과의 오랜 협력을 기대하고 있습니다.다음은 참고하실 수 있는 주요 정보입니다.FAQ:1. 귀하의 MOQ는 무엇입니까?1 세트는 괜찮습니다2. 배송 시간은 어떻게 되나요?배달 시간은 약...

뉴스

범주:

검색 결과가 없습니다!

케이스

범주:

비디오

범주:

검색 결과가 없습니다!

다운로드

범주:

검색 결과가 없습니다!

모집

범주:

검색 결과가 없습니다!

추천 제품

검색 결과가 없습니다!

왓츠앱

왓츠앱 핸드폰

핸드폰